Hypothesis about the ancient

constructive and assembling techniques

Building a stone bridge, more then 400 years ago,

was really a feat and most probably the highest difficulties of the time were the

following:

§ structural and architectural design was not determined trough a knowledge of the

theoretical principles related to stability and resistance but trough the knowledge of the

causes of collapses and effects of loads: therefore anything new would have meant

something unforeseeable;

§ the building of a wooden false work, (centering), that could bear the huge load of the

stone blocks with limited settlings has always been one of the most remarkable issues of

large ancient stone structures;

§ transporting and lifting heavy stone blocks was a technological issue that was strictly

linked to the times of performing the works which had to be controlled to avoid collapsing

risks related to the season variations of the river water level.

Unlikely, no historical document is yet available about the tale of the bridge yard, with

organisation notes, constructive methods, difficulties found: therefore, what above

mentioned, is mainly an hypothesis based on similar cases.

But what follows is more scientifically proved by the architectural analysis held on the

ancient bridge surveys.

The centering was most probably a wooden one; nothing is known about the exact

configuration of it, apart from the fact that some recurrent discontinuities have been

found in the arch intrados, which may have been caused by different sectors of the arch

false work, (centering - scaffolding); these sectors may have been defined by the length

of the master beams used for the structure.

It is most likely that the ancient centering was not strong enough to bear the loads of

the stone blocks without settlings: this may be proved by the fact that, by comparing

north and south elevation, it is possible to note that next to the springers the rows were

much more regular and well built, with little variations of levels. While, proceeding to

the key stones, irregularities increase: rows are proceeding not parallel, levels are

changing from north to south in a range of about 10 centimetres. Presumably, the more the

centering was loaded, the more it underwent to unforeseen settlings that were more

remarkable by the south side, as it can be observed with the numerical analysis of the

co-ordinates. To recover the settlings, it is possible that wooden wedges were used, of

which there are traces in many spots of the intrados surface of the vault, (some steps

between adjacent voussoirs may be surveyed even in the assembled blocks recovered from the

river). The use of wooden wedges was probably performed with very small ones next to the

springers in order to adjust the voussoirs and to match their joints and was performed

with bigger ones towards the top, to correct the geometry following the planned design

shape.

Even if arch stones were of remarkably different dimensions, the preparing and assembling

procedures were not randomly performed,and what is even more important to stress, the work

over the centering was most likely to be quite limited to the assembling: in other words

most of the work like stone cut and carvings of slots were performed off-site. The above

statement may be proved by the following observations:

§ positioning of voussoir joints was, as in ordinary masonry works, accurately shifted to

guarantee an efficient interconnection of the stone blocks;

§ positioning of cramps and dowels, and related slots and channels, required the exact

knowledge of the stone dimensions and of their joints positions of adjacent rows of

voussoirs to avoid interference between metal strengthening devices and joints;

§ stone voussoirs were quite variable in the vault, but the ones belonging to the same

row were of very close transversal base dimensions: average variation range cm 0.5-2 in a

length of almost 4 metres, which is an accuracy quite higher than the average followed for

all the other parameters.

From the above observations it is possible to deduce that, at the time, they were using

different stone voussoirs for the bridge vault of different size and shapes, (due to the

natural availability of the quarry, where it seems that some natural weakness veins

compelled to limit the dimensions), but each row of the vault was accurately pre-selected

and picked from a temporary deposit of rough blocks. Each row was composed of voussoirs of

very close intrados dimensions, and was prepared next to the preceding one in regard of

the joint positioning and of the metal elements positioning. Dowels were previously

assembled off-site and related slots were prepared. This procedure was most likely to be

performed on groups of rows and not on couples to avoid that the assembling could be

stopped by the lack of prepared arch rows. Over the centering it wouldn't have been

possible to manage all the vault requirements unless an efficient communication of

dimensions were performed between the working teams over the centering and the working

team off-site.

Despite the accuracy concerning the transversal thickness of arch rows was accurately

performed, the raising of the rowswas quite irregular towards the top, most probably due

to the mentioned centering anomalous settlings. This increasing inaccuracy has been

recovered wholly in the three top rows at the key stone level, where assembling has been

performed regardless of the previously surveyed criteria, and even a variation of cm 11 of

the intrados size has been checked in only one row.

Most probably the arch top rows of voussoirs are the prove that the two teams of workers

were not in contact and not co-ordinated in the carrying-on of their works. It may be

possible, also, that something was going wrong with the centering and that final rows have

been quickly assembled to stop the gradual settling of the vault. We shouldn't forget that

the vault was about 145 m3 of stone which weighted almost 300 tons over a wooden temporary

structure.

Technical description of

procedures for amendment of the wall from the level of abutment bottom to the level of

cornice

INTRODUCTION

The assumptions of work performance on amending the wall from the level of abutment bottom

to the level of cornice, which are the subject of this project, are:

· quality performed works on amending the wall beneath the level of abutment bottom

· excavation and archaeological works inside the abutments of the bridge until the level

of injected mass appearance (assumption is that injected mass appears on the cornice level

on both sides of the bridge)

stone wall reparation

Works on amending the wall in

mentioned segment are composed of amendments of abutments (injecting the wall through

joints, replacement of damaged stones on the wall surface and re-pointing), and injecting

the wall approximately 1.0 m into zone of injection works already done in the section of

foundation.

Amendment of wall

Amendment of wall is done by injection and placing the constructive reinforcement into

drills. The main purpose of injection procedure is filling the possible smaller cavities

and cracks on joints between the layers.

Previously done injections in the mentioned wall in section of foundation have shown small

consumption of mixture (respectively small penetration into the wall) in between the weak

and strong connected layers of conglomerate. Only in unconnected layers of conglomerate

the consumption of mixture was somewhat larger.

THE WALL

The wall in the mentioned zone of this project, according to geotechnical research works,

is composed of layers of firmly connected conglomerate alternately with layers of weakly

connected conglomerate, on both banks. Layers are approximately horizontal with irregular

changes of layer thickness.

That kind of structure is also seen on upstream and downstream parts of the bank.

AMENDMENT OF THE ABUTMENTS ON THE MENTIONED LEVEL

Amendment of the abutments is done by injecting the wall through joints, replacing damaged

stones on the wall surface, re-pointing, as well as re-building on the surface where the

stones are missing. The purpose of injecting is better solidity of the wall, decreasing

the amount of voids in the wall, and accomplishing better touch with the wall. Minimizing

the voids in the wall is necessary for making the wall less permeable in order to stop the

leaking of grouting mixture when injecting behind the wall.

The works will be done according to following schedule:

· Cleaning the joints.

· Replacement of the damaged parts of the stone

· Re-building on the places where the stone is missing

· Closing the joints with lime mortar that has the colour and content according to

demands of the conservator.

· After consolidation of mortar in joints, drilling of injecting drills f 25 mm needs to be done. 5 drills on 1 m2 of the

wall surface are foreseen. Injecting the wall will be done only from one side so the

length of the drill is foreseen in the wall thickness. According to researches, the wall

thickness of the mentioned segment is 60 – 80 cm.

· Injecting is done with factory-made mortar “Calx Romana” under the pressure

of 1 bar.

· Control of performed work is done after completed consolidation of grouting mixture.

Two procedures are suggested: either ulterior injection of a specific zone where

additional filling of grouting mixture can not be more then 10% of previously determined

quantity that was injected, either by disclosure of few square meters of the wall surface

in order to visually determine penetration of grouting mixture.

Reinforcement is placed constructively for strengthening cracks between approximately

horizontal layers (drills are vertical on layers).

Injecting will be done with downward method. Approximately one drill on each 1.5 x 1.5 m

of surface is foreseen, but the real schedule of drills will be adjusted according to the

existing situation of the walls within the surface of abutments. The amendment includes

the zone of 6.0 m from the bridge foot, which is characterized as a zone of possible

influence of the bridge load. Schedule of drills on the right bank shown in supplements is

conditional because the archaeological researches and excavations to the level of cornice

are not done yet. Some drills are done slantingly with the purpose of penetration into the

wall beneath the walls of larger thickness.

On the right bank vertical drill 6.5 m length is foreseen, and on the left bank 8.5 m

drill. Length is determined as a distance from cornice level to the depth of penetration

conglomerate (breca) layers is not expected in the mentioned zone, according to

geotechnical researches.

Control of performed work

Control of performed work on amending the abutments will be done with method of ulterior

injecting or with disclosure of injected part of the wall.

Conducting control is foreseen on three places on each abutment wall.

The control of performed work on improving the wall will be done by taking out cylindrical

testing samples by ulterior drillings. Vertical drilling on three places on each bank is

foreseen. The locations of performing control works will be determined by supervising

engineer.

Technical

description of preliminary scaffold design

1.1 GENERAL

In order to enable undisturbed work on construction of new abutments and the remaining

parts of the arch, the main scaffold girders in base shall be mounted nearby bridge, as

well as concrete foundation and piers. Fully protection of stone walls will be achieved in

a way that connection between concrete and stone will be coated with appropriate folie.

Fully structural stability of piers, i.e. stone part of abutment shall be carried out with

pre-stressed anchors, which shall have function of abutment stability even after removal

of scaffold, because they'll be completelly injected.

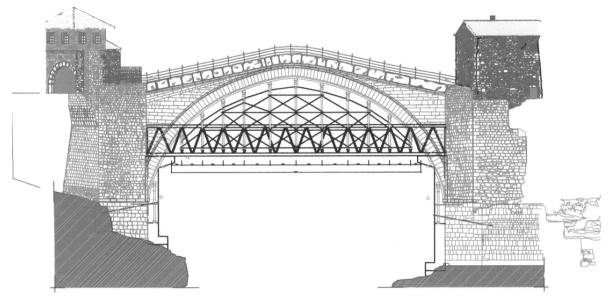

longitudinal view to the bridge

scaffolding

1.2 DISPOSITION OF THE SCAFFOLD

CONSTRUCTION

In longitudinal sense, centring consists of two main triangle steel trusses, mounted

nearby bridge (from the both sides).

Steel trusses are supported on neoprene bearings with consoles, anchored with pre-stressed

anchors in finishing phase of scaffold mounting.

Those console pre-stressing of steel trusst contribute reduction of bending moment in the

field, as well as time i smaller deflection skele.

In order to eliminate the wind influence, the steel trusses shall be mutual connected with

bracing in three positions, in the middle and two meter from the bearings from the both

sides. Wind bracing shall be fitted in upper and lower zone according to principles of

propping and tensioning.In accordance with enclosed disposition, on main longitudinal

steel trussed girder shall be fitted steel cross girders, on which heavy scaffold Æ 159/150 (5 pipes in each esction) shall be

supported. Those steel pipes shall be mutual stiffened with steel pipes Æ 48,3 mm and standard rigid coupling in

horisontal way (two pipes in both, longitudinal and cross direction).

cross section of the bridge

centering

Besides, steel pipes joints shall be diagonally stiffened in accordance with enclosed

drawing.

At the top of the pipes Æ 159/150 shall be fitted typical height regulators, which provide up and down

scaffold lifting up to 170 mm.

On height regulators shall be packed wooden beams – centring girders. Centring shall

be constructe by 4 board, 4,8 mm thickness, 150 mm minimal height. On centring shall be

fitted small board formwork beams, which follows the level of intrados, i.e. geometry of

arch.

The main girders of scaffold shall be fitted above the level 50,70 mnm, i.e., the bottom

edge of the steel truss is at the level 51,00 mnm.

1.3 SCAFFOLD CONSTRUCTION CAMBER

In enclosed structural analyses for main steel truss girders were given three phases of

analyses.In first phase were given influences of own weight and weight of formwork

centring and scaffold. For this influence, deflections are 1,96 mm. This influence could

be eliminated at once with above described height regulators. In second phase of analyses,

besides own weight, was given influence of mason work on bridge stone arch. The biggest

deflections of those influences were in the middle and they are 6,25 mm. This influence

could also be eliminated with height regulators.

In third phase of analyses were given deflections of total weight of bridge, arch and own

weight, and it is 12,39 mm. Concerning that deflection of own weight is permanent, and

that builded arch take over loading up to 3%, so the total deflection of bridge loading

could be assumed approx 7,00 mm.

Besides those deflections, in scaffold construction camber shall be counted deflection of

bridge construction, which is 2,2 - 25 mm.

In consultation with Supervisor, in each point of centring supporting shall be established

precised level of camber, on which the scaffold construction shall be constructed.

1.4 RELEASING OF SCAFFOLD CONSTRUCTION

Releasing of scaffold construction means separation of scaffold from the main construction

and taking over of loading to basic construction. Releasing of scaffold in this case shall

be done step by step in four phases in a way to release first in top of the arch, i.e.

around top of the arch, in each phases 25% of scaffold camber. skele. In Main design of

scaffold construction shall be done precised schedule of scaffold releasing, plan of

working manpower etc.

Electricity

supply for the crane

From 19th to 23rd of October 2002, preparatory works for the crane

power supply were performed. The electricity was brought to the site from the nearby

electricity transfer case. Five pillars have been erected to carry the electric cable.

lying of the foundation tubes for

the pillars

On the Site, close to the crane, the electric switchboard was installed.

On the 25th of October, after authorised approval, the electricity for the crane was

officially switched on.

Fully operating of the crane started on Monday the 28th, and it’s first task was the

removal of stone blocks from the platform.

crane is in function

High water level

From 10th to 24th of October, water levels of rivers Neretva and

Radobolja were extremely high. The reason for this level incensement were heavy rains in

the area.

view to Neretva on 15th of October |