2.3.5 Technological devices

As already mentioned, the bridge

stone elements were reinforced trough the use of peculiar technological devices made in

hand forged iron, and placed across the connection joints following different typological

assembling methods. Basically these iron connectors were of two different types: cramps

and dowels, and they were applied to the stone elements into slots that were purposely

carved with their bottom slightly widen in order to avoid untying. Metal connectors had,

as well, their edges widen, and, once assembled, it was poured melted lead in the slots to

finalise the assemblage.

The above described technique allowed, together with the use of mortar,

a quite efficient connection system which was extensively performed for the voussoirs, in

the vault, where three different groups of connectors were adopted: dowels among row

joints, cramps for side joints, and extrados cramps mounted in a continuous layout to

guarantee a tying action. All the other stone elements of the bridge were linked by metal

connectors, including the parapets which were doweled to the upper cornices and linked one

to each other trough visible cramps placed on top edge.

Most of these iron strengthening were hidden and protected in the inner

parts of the joints, also to avoid rust; nevertheless, being those elements hand forged

and partially winded by the lead, they could not get easily rusted: as it has been noted

for the recovered stones, which after being 4 years in the river waters, were quite

damaged but considerably in good condition.

For what concern detailed explanation of the assembling techniques, the

methodology used, and the dimensioning criteria, refer to chapter 9 of this report.

2.3.6 Construction materials

A detailed and scientific analysis

of the construction materials used for the bridge construction, has been provided trough

laboratory tests by LGA Company; here next only a brief list of the construction materials

used is provided:

- most of the stone elements of the bridge like vault, cornices, spandrels and parapets

were made in tenelija stone (Category I), which is a local oolithic limestone rock of

light and warm colour and high porosity of a resistance to compressive strengths of about

20 MPa; (availability Mukoša Quarry);

Tenelija stone |

Porosity |

23% |

Specific density |

27KN/m3 |

Wet density |

21KN/m3 |

Dry density |

19KN/m3 |

Moisture content |

8% |

Uniaxial compressive strength |

20Mpa |

E modulus |

13.000 MPa |

the pavement and the stone slabs over the lightening voids were in krecnjak

stone, a limestone hard and resistive marble-like of light colour;

metal connectors, cramps and dowels, were in forged iron as well as the fence;

lead was used for the connectors and for the assembling of the fence;

mortars of different types and compositions have been found all over the structure:

refer to LGA reports for detailed analysis;

"terra rossa": red coloured aggregates with a remarkable content of bauxite

were settled in a layer underneath the pavement.

A special document, as summary of the construction materials and

their correct denomination, has been asked to LGA by GE. For this special issue credits

are given to LGA and to eng. Gregor Stolarski, the document is here fully reported:

Tenelija (local name) for the oolithic limestone, uniformly

granulated (visible grains), ivory - whitish coloured stone; denomination used in the LGA

reports is either Tenelija or oolithic limestone; also more grey coloured type is

encountered;

- Breca

(local name) or natural breccia or conglomerate; greyish, very

coarse (gravel size well rounded grains) and very porous stone, which is encountered

directly at the location of the bridge in Neretva river bank formations; it presents a

secondary cementation of a large size river sediment; in the LGA report mostly named

Breca, also as conglomerate by others (e.g. CONEX);

- Krecnjak - dark grey

, the dark-grey and black-grey section of limestone

blocks at the right bank downstream wing wall foundation (few rows of stones only,

possibly of origin older than Stari Most) covered partially with modern restoration -

plaster; this section was wrongly named "marl" in early LGA paper;

- Krecnjak - massive

, a massive, white - grey limestone used in the

rough irregular masonry works e.g. of the towers, in the fill masonry of the Stari Most

and in the stiffening rib; sharp-edged stones of small size, very hard stone;

- Krecnjak - marble

, massive, marble - alike limestone, which is used in

the pavement slabs; also encountered locally in aggregates of fill mortar;

- "Sandstone"

(as direct translation of the local name), geologically a conglomerate

of white smaller grains (when compared to Breca) - not a classical "sandstone";

Its individual grains are very sharp edged and are embedded into a sandy, iron-oxide

coloured cementation matrix; the stone is hard and porous; it is represented by only few

stones within the monument, found e.g. as window frame in Helebija;

- Miljevina

, a massive limestone of oolithic origin but with no visible

grains, harder than Tenelija (found in the same quarry Mukoša), a

"mudstone" in a sense; used obviously for recent or younger repair works only on

very few spots;

Below the pavement slabs two different mortar layers are

defined:

pink lay mortar for the stones, few centimetres thick only below the

stones and present also still in the joints between the slabs of the pavement; laid as

real mortar

- dark red and brick red mortar

layers below the pink one; defined as foundation

or levelling layer for the final pavement cover; this "mortar" has a

composition of an ancient mortar, have been placed under low workability (low moisture

content) and compacted manually; the thickness is probably less than 10 cm but cannot be

clearly defined without precise archaeological studies, since the red colour has spread

down to the mineral layers, originally not belonging to the pavement formation (levelling)

layer.

- Additionally a mineral fill layer has been placed historically under the dark red mortar

as equalising foundation layer. This layer contained sand and clay of intense red colour

and has been defined by comparison to local materials as Crvenica - the red earth,

geologically: very old soil, typical for the region and for the limestone formations. From

the point of view of LGA it is not recommended to put the local red earth into the

reconstructed bridge due to the high clay content, which is above the frost resistance

tolerance level. Instead the fill mortar below should be laid to the original red-earth

level.

2.3.7 The destruction event

The Old Bridge of Mostar was destroyed in November 1993 by shelling

during recent war events; the moments in which shelling were ongoing have been filmed and

from that documentation it has been possible to gather some technical data and

observations.

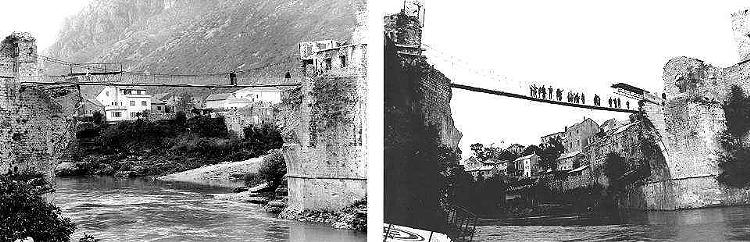

fig15 – moments before the destruction event: shelling are ongoing by the

south side

From

analysis of the remaining portions of the bridge located by the east abutment, it is

possible to observe an higher surface deterioration on the north side than in the south

one, but, as far as it was possible to see from the movie, shelling were coming from south

side and hit mostly the south east portion of the bridge over the arch reins: nowadays the

widest remaining portions of the bridge are located on that side. This seems quite strange

but it is most likely that shootings were directed also to the north elevation during

other war attacks, and this is the reason why the bridge had been protected by tyres,

(temporary structures over the footpath were instead aimed at the protection of the people

from shootings). Moreover shelling was performed with accuracy almost on the same spot in

order to cause the collapse using the minimum numbers of shells and the structure was

divided in two main parts: a small one below the arch reins by the east bank, (still

built-in and on-site), and a big one which ruined wholly in the river.

fig16

– the sequence of images of the collapsing of the bridge

From

observations of the movie it is possible to note how shells have gradually brought to the

bridge collapse:

- the load bearing arch was the main target element of the shelling: a wide portion of it

was destroyed before final collapse, (from the reins to the key stone for a thickness of

about a meter);

- other shelling which were higher than the target perforated the spandrel wall with

escaping of fill;

- the attack has been performed by people that knew the basic functioning of a bridge

structure;

- shelling was performed with the aim of causing the collapse of the bridge and not of

ruining the bridge; the bridge collapsed when a shell broke definitely the continuity of

the load bearing arch.

The above mentioned movie has helped the work for the repositioning of

the recovered stones, (see §4.3.7), since it has been possible to determine the voussoirs

that were most likely definitely lost and reduced to powder due to direct hit.

fig17

– current condition of the bridge (north and south elevation)

2.3.8 Reference dimensioning: the

numbers of the bridge

A schedule with most significant data of the bridge is here next

provided to allow preliminary evaluations during the on-site works:

data concerning geometry |

unit |

value |

north span |

cm |

2871 |

south span |

cm |

2862 |

north maximum

raise – measured from east impost level |

cm |

1206 |

south maximum

raise – measured from east impost level |

cm |

1205 |

average height

above river level (depending on seasons and on river waters) |

cm |

1600-1800 |

lowering of

the east springer in respect of the west one (by north side) |

cm |

13 |

lowering of

the east springer in respect of the west one (by south side) |

cm |

12 |

intrados

curvature length north side |

cm |

4058 |

intrados

curvature length south side |

cm |

4036 |

extrados

curvature length north side |

cm |

3607 |

extrados

curvature length south side |

cm |

3638 |

thickness of

load bearing arch |

cm |

395 |

thickness of

spandrel walls |

cm |

60-85 |

thickness of

lower cornices |

cm |

60-70 |

thickness of

upper cornices |

cm |

80-90 |

thickness of

parapets |

cm |

20-26 |

average height

of parapets (measured by the outer side) |

cm |

90-92 |

raising of the

bridge footpath |

% |

18-19% |

raising of the

bridge footpath |

cm |

270 |

data

concerning the quantification |

unit |

value |

number of rows

in the load bearing arch |

n° |

111 |

number of

voussoir per row (the average is anyhow 3-4) |

n° |

2-5 |

average

dimensions of a voussoir (volume = 0.32 m3; weight about 640 kg) |

cm |

40×80×100 |

highest length

of a voussoir |

cm |

258 |

highest volume

of stone block before final cut (weight about = 2500 kg) |

m3 |

1.25 |

| |

|

|

number of main

stone elements of the whole bridge (pavement not included) |

n° |

1006 |

number of

stone elements of the whole bridge (pavement not included) |

n° |

1088 |

number of

voussoirs in the load bearing arch |

n° |

456 |

number of

spandrel stones |

n° |

425 |

number of

cornice stones |

n° |

157 |

number of

parapet stones (including small element by south-east side) |

n° |

50 |

| |

|

|

number of

metal cramps for the side joints of the vault |

n° |

666 |

number of

metal cramps for the extrados of the vault |

n° |

550 |

number of

metal cramps for the lower cornices |

n° |

91 |

number of

metal cramps for the spandrel stones |

n° |

197 |

number of

metal cramps for the upper cornices |

n° |

124 |

number of

metal cramps for the parapet stones |

n° |

46 |

total number

of metal cramps in the bridge |

n° |

1674 |

| |

|

|

number of

metal dowels in the vault |

n° |

717 |

number of

metal dowels in the parapets |

n° |

93 |

total number

of metal dowels in the bridge |

n° |

810 |

| |

|

|

volume of the

load bearing arch |

m3 |

145 |

volume of the

load bearing arch plus quarrying tolerance |

m3 |

191 |

required

volume of stone to be cut for the load bearing arch |

m3 |

202 |

required

volume for spandrel stone |

m3 |

102 |

required

volume for cornices stone |

m3 |

33 |

required

volume for parapets stone |

m3 |

19 |

required

volume of stone for the whole bridge (pavement not included) |

m3 |

356 |

data

concerning co-ordinates |

unit |

X value |

Y value |

Z value |

north east

springer (a.s.l. level - referred to local origin) |

m |

23.02 |

41.02 |

46.71 |

north west

springer (a.s.l. level - referred to local origin) |

m |

50.69 |

33.35 |

46.84 |

south east

springer (a.s.l. level - referred to local origin) |

m |

24.12 |

44.81 |

46.72 |

south west

springer (a.s.l. level - referred to local origin) |

m |

51.70 |

37.17 |

46.84 |

| |

|

|

|

|

north east

springer (referred to relative origin: north east springer) |

m |

0.00 |

0.00 |

0.00 |

north west

springer (referred to relative origin: north east springer) |

m |

28.71 |

0.00 |

0.13 |

south east

springer (referred to relative origin: north east springer) |

m |

0.04 |

3.95 |

0.01 |

south west

springer (referred to relative origin: north east springer) |

m |

28.66 |

3.95 |

0.13 |

2.3.9 Classification and

nomenclature

In order to avoid any

misunderstanding due to naming of different bridge stone structures and elements, here

next it has been given a reference scheme with which it is possible to identify clearly

the terms that have been used in the report.

fig18 – bridge elevation with identification of the terms used

fig19

– bridge axonometric cut view; on the left classification codes according to flow

chart of next page; on the right other terms used in the report and in the design

In

addition to what showed in the above pictures, some other terms may be underlined:

- bridge span = arch span = distance among springers

- bridge raise = arch raise = distance among springer and key stone levels

- elevation = front view

- joint = connection line between two adjacent stone elements

- abutments = masonry structure that bears the thrust of the bridge

- masonry work = stones assembled with mortar

- ashlar work = accurately cut stone blocks assembled with mortar

- metal cramp = forged iron U shaped element used to assemble bridge stone blocks

- metal dowel = forged iron I shaped element used to assemble bridge stone blocks

- stone carve = surface stone cut – incision

- carved slot = hole in the stones for dowels

- carved channel = surface long incision for pouring the lead - feedhead

- arch centering = temporary structure used for assembling the bridge arch

- arch falsework = arch centering

- archivolt = bridge arch, vault

To allow an easier explanation of

all the matters and issues concerning the stone elements it has been worked out a simple

classification an code system that is here next showed in the flow chart. This

classification system has been used and enlarged in the report for the purposes of the

design.

fig20

– stone classification and code system

The

main subdivision among arch stone and other bridge elements has been performed since the

arch voussoirs are quite peculiar and are supposed to match higher structural requisites.

This classification has been adopted in the report, in design drawings

and in design charts for stone final cut. |